Overview: American Custom Drying (ACD)

American Custom Drying (ACD), founded in 1969, is based in Burlington Township, NJ, with additional facilities in Tullytown, PA, and Mountain Top, PA. Specializing in services such as spray drying, liquid batching, and microencapsulation, ACD caters to industries including food, pharmaceuticals, and cosmetics. They have a production capacity of up to 200 pounds per hour and provide flexibility in batch sizes. Their certification includes SQF 2000 Level 2, HACCP, and ISO 9001, ensuring adherence to quality and safety standards. For inquiries, contact via email at info@acdprocessing.com.

Phone numbers:

Emails:

About American Custom Drying (ACD)

American Custom Drying (ACD) Overview

OK, let's review what we've got on American Custom Drying (ACD), a player in the co-manufacturing scene. ACD was founded in 1969 and operates out of Burlington Township, NJ. This team consists of somewhere between 11 and 50 employees, and their revenue range is believed to be between $1M and $10M. If you're interested in reaching out, you can call them at +1 609-387-3130 or drop them an email at info@acdprocessing.com. They're also on LinkedIn if you want to follow them there.

Co-Manufacturing Services and Capabilities

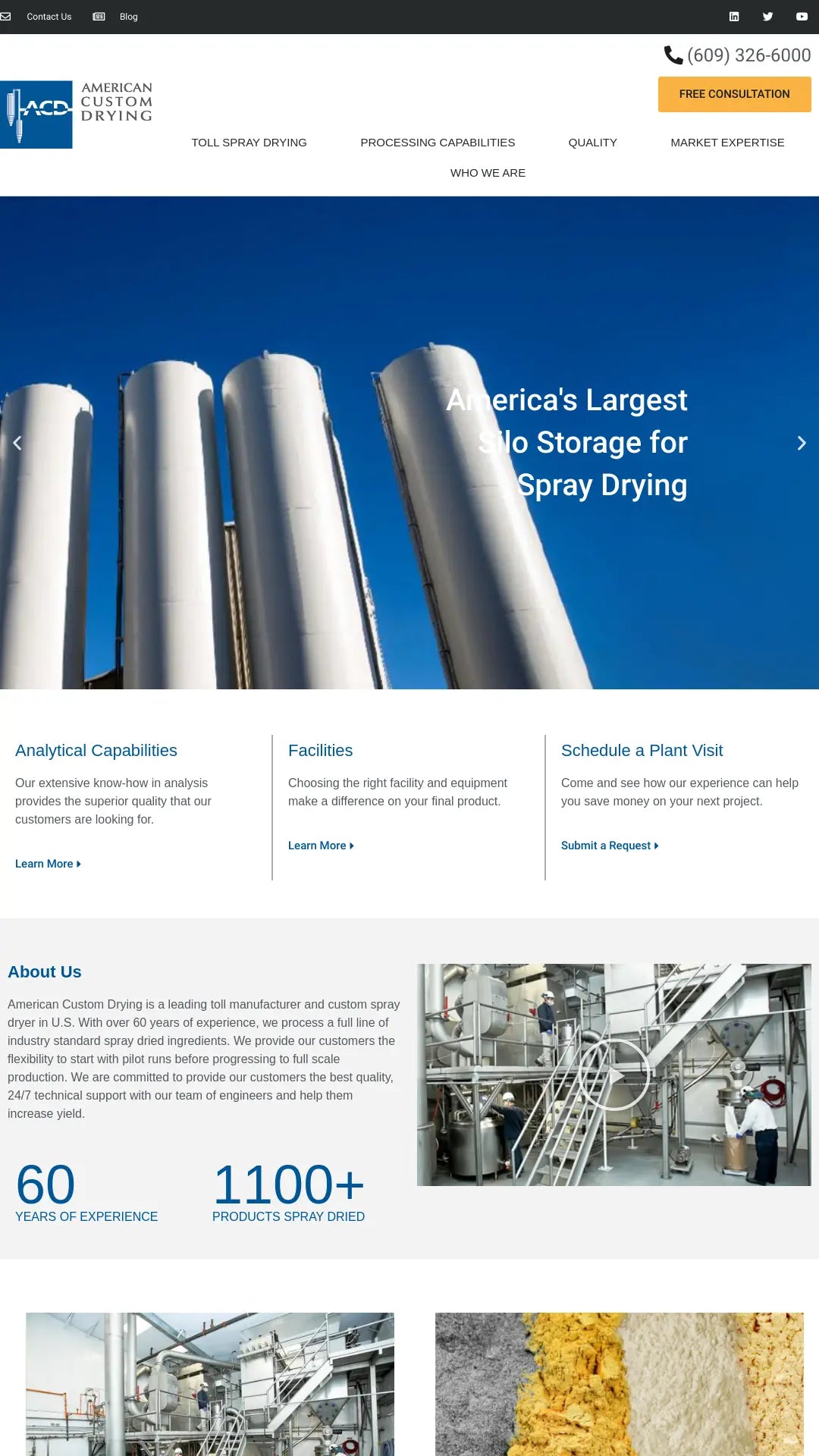

At the core of ACD's operations are their co-manufacturing services, which include spray drying, liquid batching, and microencapsulation. Their expertise spans across various industries like food, pharmaceuticals, and cosmetics. The company provides toll spray drying, enabling clients to seamlessly transition from initial R&D phases to full-scale commercial production.

The technical capabilities of ACD are quite robust. They utilize controlled environments and high-pressure atomization technology within their facilities to ensure efficient and effective spray drying. An on-site analytical lab is part of their setup for quality checks and process refinement, ensuring that the final product meets necessary standards.

Specializing in Specialty Ingredients and Nutraceuticals

Now, let's talk about what ACD can do for specialty ingredients and nutraceuticals. They focus on transforming liquid ingredients into stable, free-flowing powders through spray drying. This process helps maintain the quality and shelf life of the products without relying on preservatives. Such solutions are vital for producing high-quality nutraceuticals, which are gaining traction across health-focused sectors.

Production Capacity and Minimum Order Quantities

ACD’s production capacity is designed for flexibility. They can evaporate up to 200 pounds per hour and are equipped with multiple dryers to handle varied batch sizes. Their minimum requirements start at 50 gallons for trials and can scale to a minimum of 500 pounds for commercial runs, offering a good range for different production needs.

Certifications and Compliance

ACD adheres to multiple certifications, underscoring their attention to regulatory standards. These certifications include SQF 2000 Level 2, HACCP for food safety, and ISO 9001. Such certifications are essential for ensuring quality management and food safety, particularly in industries like food and pharmaceuticals.

Facility Locations and Accessibility

Besides their headquarters in Burlington Township, NJ, ACD has additional facilities located in Tullytown, PA, and Mountain Top, PA. This setup allows them to cater to a broader range of clients and industries while maintaining efficient production lines.

Connect with ACD

If you’re interested in learning more about American Custom Drying or considering a partnership, you can check out their official website for more details. Feel free to call, email, or check their LinkedIn page for the latest updates or to get in touch with their team.

That’s the lowdown on ACD—an established name you might want to consider in the world of custom dry processing and co-manufacturing. Whether you're looking to scale up from pilot runs or delve deeper into R&D, ACD’s range of services and technical expertise offers a versatile approach to meeting industry needs.

- Choosing a selection results in a full page refresh.

- Opens in a new window.