Overview: Anderson Custom Processing

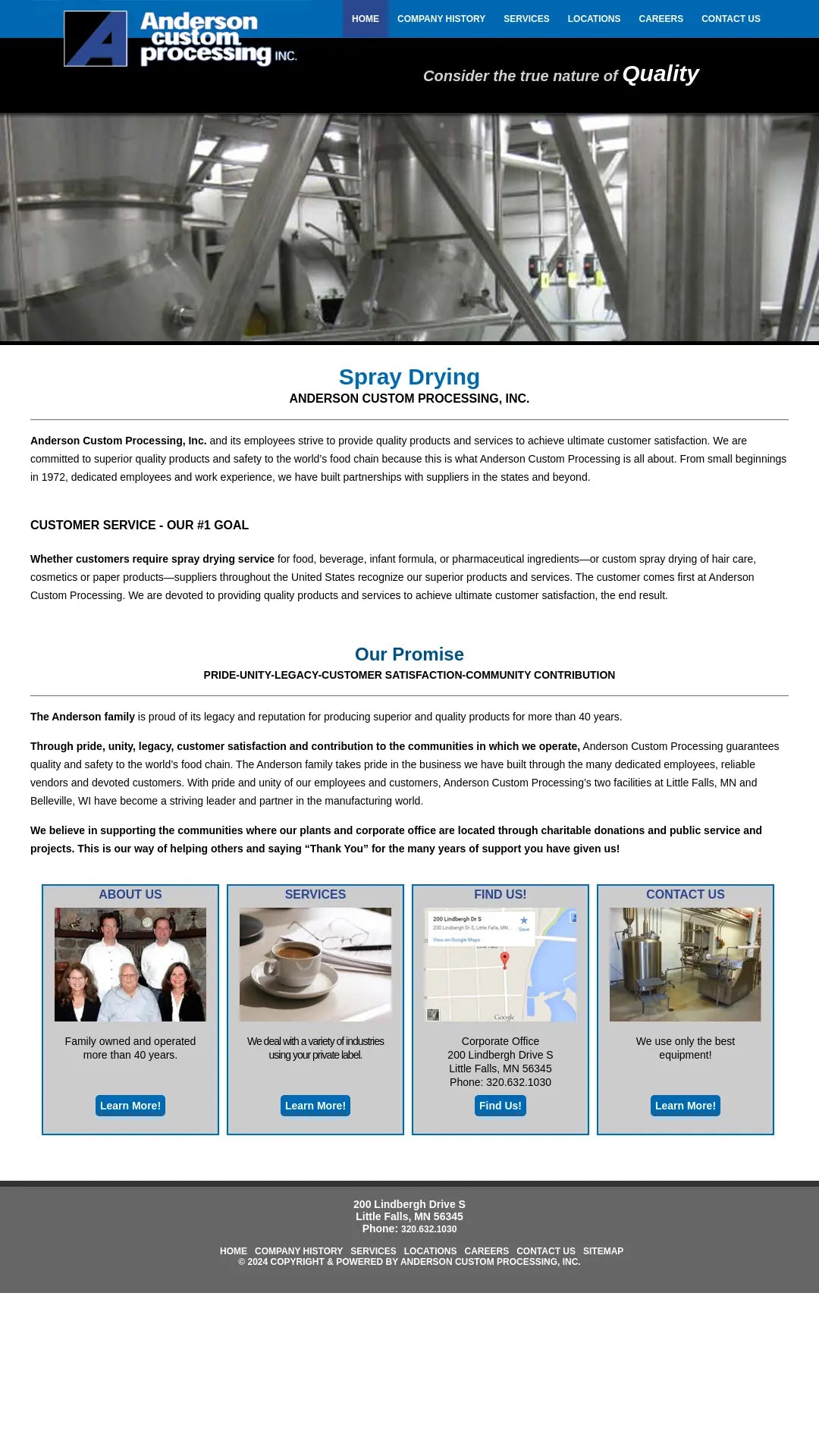

Anderson Custom Processing, based in Little Falls, Minnesota, has been operating since 1972. They specialize in custom spray drying with facilities in Minnesota and Belleville, WI, featuring dryers capable of high water evaporation rates. Their services include food ingredients and private labeling, meeting clean room standards for quality assurance.

The company, employing 11 to 50 people, is BRC certified and has completed the SMETA 4-Pillar Audit. Anderson Custom Processing's capabilities and certifications support their role in food, beverage, and pharmaceutical industries, with revenues between $1 million and $10 million.

Phone numbers:

About Anderson Custom Processing

Understanding Anderson Custom Processing

OK, let's review what we've got on Anderson Custom Processing, Inc. Located in Little Falls, Minnesota, this company has been around since 1972, making it quite a longstanding player in its field. They operate with a workforce that falls somewhere between 11 and 50 employees, and the company generates revenue in the range of $1 million to $10 million.

Co-Manufacturing Specialties

Custom Spray Drying

Anderson Custom Processing offers custom spray drying services—a pretty big deal if you're dealing with food, beverage, infant formula, or pharmaceutical needs. They’ve got five dryers in two different locations, and they're set up to handle high-efficiency water evaporation rates. Each dryer at the Little Falls facility can manage 2,000 to 3,500 pounds of evaporation per hour. In Belleville, WI, their other facility, they’ve got two dryers, each capable of 4,000 pounds per hour.

Food Ingredients & Infant Formula

These guys are into food ingredients and even infant formula. Their capabilities extend to providing tailor-made options for specific client needs, particularly in private labeling. However, if you're looking at minimum order quantities, that's something you'd have to discuss directly with them.

Technical and Service Insights

Packaging and Clean Room Standards

Service-wise, they provide packaging solutions using bags, boxes, drums, and totes—whatever fits the requirement. Their production processes meet clean room standards, especially crucial for micro-sensitive products. This ensures high levels of quality control.

Certifications and Operational Standards

Anderson Custom Processing is BRC certified and has undergone the SMETA 4-Pillar Audit. These certifications address quality, safety, labor standards, health, and environmental measures. Such certifications can often be seen as a plus, facilitating adherence to regulatory standards and possible client requirements.

Want to Know More?

If you're interested in reaching out or need more details, you can give them a call at +1 320-632-1030. For more information, you could also visit the Anderson Custom Processing website. While an email and Linkedin page details are unknown right now, keeping an eye on their website for updates might be useful.

There's a lot to think about when considering a co-manufacturer like Anderson Custom Processing, especially with their diverse capabilities in the food and pharmaceutical industries. Whether it’s spray drying or custom food ingredient solutions, they seem to have the technical horsepower and certifications to meet complex manufacturing needs.