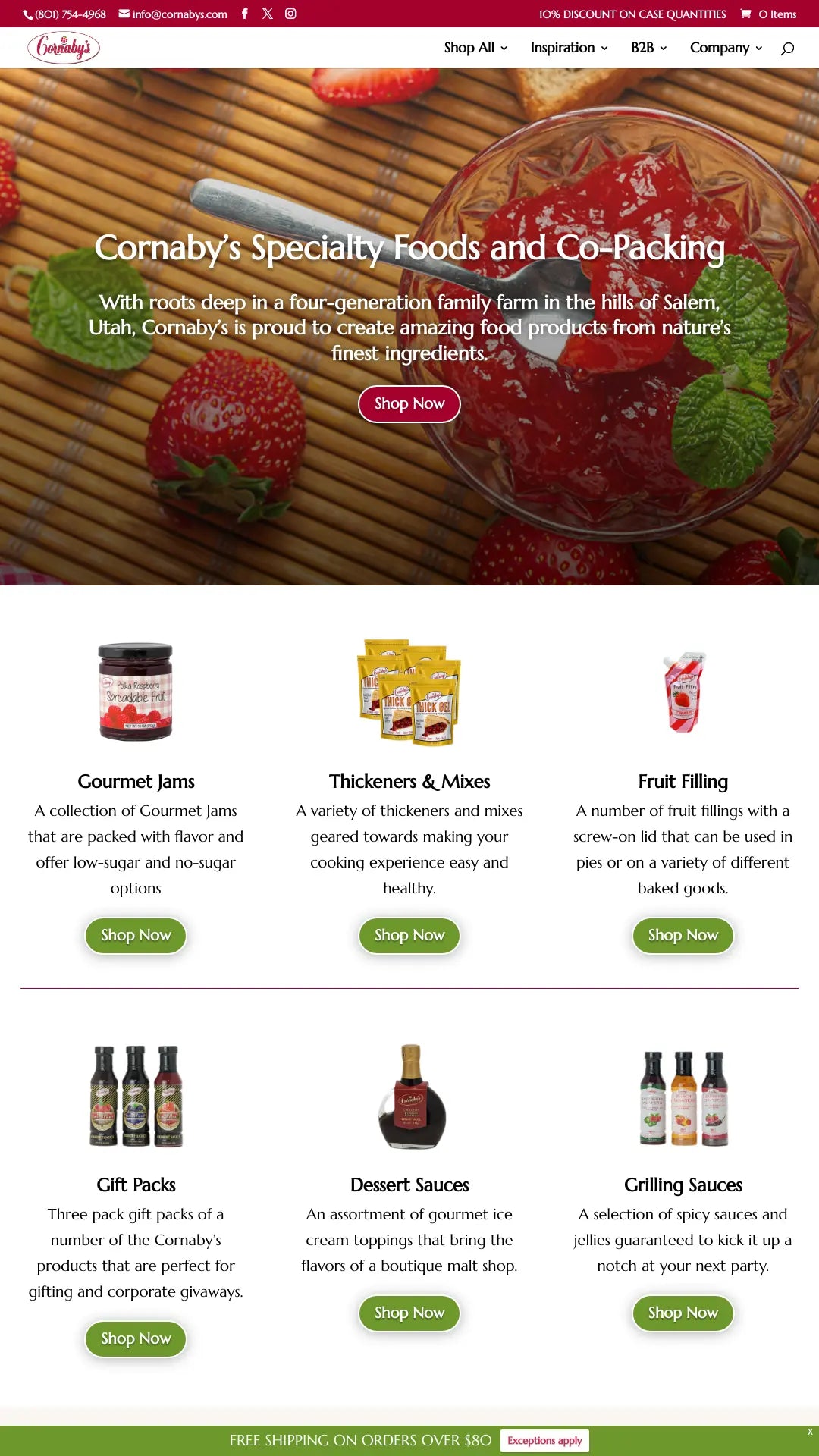

Overview: Cornaby's

Cornaby's, based in Payson, Utah, operates from 1693 American Way with a team of 11 to 50 employees and generates revenue between $1M and $10M. Specializing in jams, sauces, and thickeners, they use natural, gluten-free, and non-GMO ingredients. Their flexible co-manufacturing services include co-packing, private labeling, and custom formulations. Advanced equipment such as temperature-controlled kettles and automated fillers support their production capacity of 8,000 jars per shift. For inquiries, contact them at info@cornabys.com or visit their website.

Phone numbers:

Emails:

About Cornaby's

Cornaby's: A Co-Manufacturing Partner in Utah

OK, let's dive into what we've got on Cornaby's. Based in Payson, Utah, Cornaby's Specialty Foods operates from their headquarters at 1693 American Way. This family-run business is nestled within a scope of 11 to 50 employees and has carved out a place in the food industry with revenue somewhere between $1M and $10M. Now, while we don't have a confirmed founding year, it's clear that Cornaby's has established itself as a versatile player in co-manufacturing. Let's explore what makes them tick.

Jams, Sauces, and Thickeners

Cornaby's provides a range of products like jams, sauces, and thickeners, specifically focusing on natural ingredients. They accommodate various dietary needs with gluten-free and non-GMO options. These offerings aim to cater to both home cooks and professional kitchens, providing ease of use and quality in cooking and baking.

Co-Manufacturing Services

When it comes to co-manufacturing services, Cornaby's is flexible. They engage in co-packing, private labeling, and custom formulations. This means they can collaborate with different clients to create food products that meet specific requirements. It's worth noting that such adaptability allows them to participate in diverse markets and accommodate unique production needs.

Technical Capabilities

Cornaby’s operates using advanced technical capabilities. Their equipment includes temperature-controlled kettles, automated fillers, and induction sealing machines. Such tools are crucial for maintaining product quality and safety, allowing efficient production handling. The company's infrastructure supports the creation of consistent, high-quality products.

Production Capacity and Minimum Order Quantities

In terms of production capacity, Cornaby's can crank out up to 8,000 jars per shift, meeting both retail and bulk demand. While details on minimum order quantities are not set in stone and need to be discussed directly with the manufacturer, this flexibility suggests they are capable of tailoring their production to meet client needs.

Certifications and Client Information

At this point, we don't have any information on specific certifications that Cornaby's may hold. Additionally, they haven't publicly named any clients. Despite the lack of these details, their operations continue smoothly, emphasizing efficiency and quality in product creation.

How to Get in Touch

If you're interested in what Cornaby's has to offer, you can reach out to them via email at info@cornabys.com or call them at 801-754-4968. For those who like networking through professional platforms, check out their LinkedIn page for more insights.

For a deeper dive into their offerings and service specifics, Cornaby’s website is a good resource—you can check it out here.

So, in summary, Cornaby's stands as a notable player in the food co-manufacturing landscape. Their diverse product line paired with robust technical capabilities makes them a valuable partner for businesses looking to produce jams, sauces, and thickeners.

- Choosing a selection results in a full page refresh.

- Opens in a new window.